Treewell in Bekaa valley

Description of the emergency context

Lebanon hosts approximately 1.5 million Syrians who have fled the war in their country since 2011. Approximately one-third of Syrian refugees in Lebanon live in informal tented settlements (ITS)in the Bekaa region.

The influx of refugee is exarcebeting the issue of sanitation in Lebanon. Before the crisis, only 8% of the wastewater was treated according to the Lebanese Ministry of Energy and Water.

Humanitarian WASH services to ITS are based largely on unsustainable solutions, particularly water trucking and latrine desludging, as it has not been possible for various reasons to put more sustainable solutions in place.

Description of the treatment process

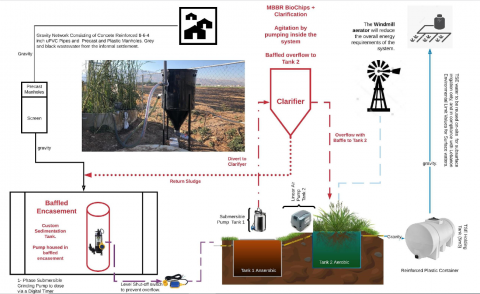

TreeWell consists of two stages of microbial degradation (anaerobic and aerobic). It is a dynamic biological system imitating: biological processes, and hydrology of natural aquatic ecosystems like lakes and wetlands. Biological processes are identical with natural microbial food-webs consisting of

bacteria, fungi, protozoans and insects. The system is totally sludge-free and does not produce odours.

Stage one: Anaerobic

Wastewater enters anaerobic tank where microbial fermentation processes are enhanced by fixed-bed biofilm carriers. This tank is inoculated with a specially blended microbial consortium.

Stage two: Aerobic

Wastewater purified in tank 1 enters highly aerobic conditions of Tank 2 which is open to atmosphere. Selected local aquatic plants and microorganisms living in their root zone (rhizosphere)

ensure final polishing of the water. The plants are rooted in a special expanded tubular netting from Denmark. This stage of treatment results in naturally purified water.

Assessment & design (feasibility)

The following assesment were done before implementing the system:

- investigate the sources of wastewater (communal kitchen, commercial activities..)

- analyse the typical behaviour of the residents at the informal settlement (quantity of wash water and the type of detergents consumed)

- conduct a survey to understand the arrangement of the settlement plots and latrines, and the lay of the land.

All these information enable to havef:

1. holding tank sizing estimates

2. a thorough understanding of the wastewater fraction

3. identification of a suitable microbial community,

4. study of particle size and screening solution to minimize load.

5. design of an appropriate reactor system configuration.

6. design of the sanitation network and access corridors.

7. evaluation of the condition of existing facilities

8. assessment of main power supply distribution board

9. designate a location for the WWTP

Construction

TreeWell requires a minimal amount of civil works and electrical, mechanical, and plumbing(MEP) preparation to install. No concrete slabs or foundations are necessary to support the system.

It needs only low voltage electricity to power the pumps Each tank has working volume of 5.5 m3 and the entire proposed solution will occupy an approximate surface areaof 20 m2 (4 tanks).

Waste Water Holding Tank

The holding tank retains approximately an entire day’s volume of wastewater (5-6m3) and a grinding sump- pump. The Sump-pump doses wastewater to the WWTP at timed intervals in order to maximize retention time throughout a 24-hour period.

The holding tank is constructed from 10mm thick steel panels that are welded together.

The dimensions of the panels are 1.5m – 3m. It is structurally reinforced to allow for extra dead weight to prevent pop-up from ground water. Also, the tank exterior is protected by a bitumen and/or epoxy paint in the interior.

Most importantly the tank is secured from water infiltration and shifting or popping up due to groundwater.

Treated Water Holding

Treated water from TreeWell Tank 2 is collected by gravity into a 5m3 reinforced holding tank. The tank is connected to a hose to allow for reuse of water by gravity.

Windmill Dimensions

The windmill dimensions is 8.53m (28 ft) from top of the wheel to the ground. The wheel itself is 1.98m diameter (6.5 ft). The total weight is 185 kilos (404 lbs). The base is 1.90m (6ft 3inch) 4-legged tower.

Windmill Reinforced Foundation

Windmill foundation is constructed from reinforced steel and concrete. The final mix design and design of the foundation was approved by the Engineer prior to installation of the Windmill at the site.

Operation and maintenance

1. Level of difficulty for O&M:

Paid 2rd party services required for unclogging the network, desludging. Remote monitoring equipment (pumps, camera, power, temp) monitored by SI.

2. Maintenance and Repair done since its start-up

Special network cleaning services, de-sludging of all the anaerobic tank settlement compartment and desludging of the holding tank. Planting of aquatic plants. Replacement internet router after storm event.

3. Daily operational activities (job description) and workload

(operational time)

Remote monitoring and control of the dosing pumps and aerator.

Automatic alternation between aerator and windmill based on air pressure, Access available for beneficiaries to clear screens and manholes. Network unclogging and desludging requires a special paid services.

4. Ease of rehabilitation

All compartments accessible to de-sludge. Fixed bed media removable and washable, pumps available in local market, linear aerators available from Contractor.

Lessons learned

not detailed

Strengths

1. Remote monitoring & dosing.

2. Autonomous, low maintenance.

3. Movable and small footprint.

Weaknesses

1. Desludging Required

2. Expensive network prone to clogging

3. Does not meet environnemental Lebanese Standards

Add new comment