Geotube - Filtration

Description of the emergency context

The project site – Unichiprang is a hilly area and is currently hosting an estimated 21,300 Rohingya refugees (ISCG Full Situation Report, 11 March 2018). Refugees are continuing to cross the border into Bangladesh, with a total of 3,236 new arrivals reportedly entering the country in February 2018 alone, bringing the number to over 5,000 newly arrived refugees so far in 2018. The population is predominantly Muslim.

Description of the treatment process

The Lime Stabilization method is a process where hydrated lime (also known as calcium hydroxide) is added and mixed manually by using simple mixing pump in pits. Addition of the hydrated lime elevates the pH that eventually kills the pathogens (disease causing micro-organism) and stabilizes the sewage, reducing odors and allowing further processing. Allowing the solids to settle in the bottom of the pit, the water can then be removed and spread over the ground area. Further, the remaining solids can be dried and be used to cover for landfill or decomposed to be used later as fertilizer. This approach uses a combination of Hydrated Lime Treatment, Geotextile Tubes known as ‘Geotubes’ and Filtration. In the first step, the faecal sludge is pumped out of the pit latrines using mechanical sludge pumps. The sludge is emptied into barrels with a lime (calcium hydroxide: Ca(OH) mix. The stabilised sludge is then poured into a Geotube from barrels through a mesh screen to remove any solid waste. A Geotube consists of a permeable membrane which allows for dewatering of the sludge.

Assessment & design (feasibility)

The latrines provided for the refugees are simple pit latrines. Pits are emptied approximately every 4 to 8 weeks depending on the number of users. In the hilly terrain of Cox’s Bazaar, the transportation of the sludge is challenging and time consuming. The pit latrines are desludged by trained operators using an Oxfam pump (Atalanta Pelican 351 Diaphragm sludge pump with Lombardini 15LD225 diesel engine) with a capacity of approximately 10 min for a 500 L pit. The sludge is transported in a 50 L barrel fixed to a pole and jointly carried by two emptiers (manual transport, see pictures below). The Lime treatment is carried out in 50 L barrels. Prior to the collection and transport of faecal sludge, 15 g/l lime (CaOH2, 2 kg per barrel) is added to the empty barrels.

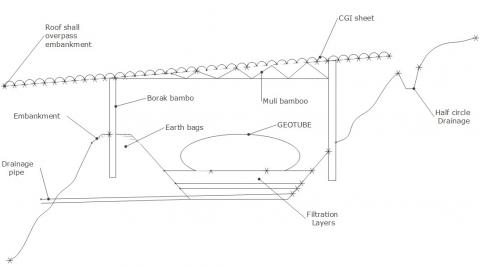

The faecal sludge from the pit latrines is removed from different ways: manual using buckets, manualy pumped using submersible pump and pumping with dedicated Oxfam trash/sludge pumps, which facilitates the mixing of the lime and the faecal sludge. Bucket desludging is used in place where it’s difficult to access with the heavy Oxfam pump. The lime creates a highly alkaline environment, which results in the inactivation of pathogens and stabilizes the sludge (if the alkaline environment of pH>12 is sustained for at least 1 hour). From the barrels, the sludge is poured through a screen (to remove any solid waste) and into the Geotube. The time the leachate filters into the sand portion of the filtration unit still need to be determined. The primary filtration units are comprised of three layers of filter media. The bottom layer is 17 cm of coarse gravel 1’’ the second layer is 14 cm of medium size gravel ½’’, topped off by a 20 cm of 2.5 fineness modulus (FM) sand appropriate for filtration. After this filtration phase, the liquid drains through a 6’’ pipe installed below the filtration media and flows through gravity force to a secondary filtration unit comprised of a 20 cm layer of medium size gravel ½’’.

The effluent from the secondary filtration phase is then discharged into the environment. The Geotube and primary filtration unit are protected with a roof to keep rain water out of the system. The solid phase of the faecal sludge is retained in the Geotube and is then emptied after a time to be determined. The Geotubes are single use and a new one must be installed after it is emptied. For the final disposal, two options are planned, depending on the final characteristics of the sludge. The first one is direct disposal of the remaining dried sludge into onto land in a nearby area and the second is, incineration of the dried sludge with basic equipment. The system was developed and designed by the Sanitation Technical Advisor of Solidarités International in coordination with the Faecal Sludge Management Technical Working Group of the WASH Cluster. There is a risk of contamination of ground water through the discharge effluent, hence the technology needs to be placed in a safe distance from boreholes, wells and other drinking water sources.

Construction

Permanent infrastructure is not permitted by the government, therefore WASH infrastructure needs to be able to be decommissioned and the use of construction materials such as bricks or cement is not accepted in the context of Cox’s Bazaar. The Geotubes are made from membrane material that is either woven and non-woven material. The project team initially piloted the non-woven membrane as it is easily available in Bangladesh and shipping time for woven material is expected to be time consuming (material pictures below). However, woven membranes have been successfully tested and may therefore be preferred, if available. Non-woven materials have mainly been used for dewatering purposes and have less been used for the treatment of sludge. Further materials required are all available in the local market such as: sand, gravel, cement, drainage pipes, bamboo, roofing, tarpaulins and fitting materials. One Geotextile unit costs approximately 60 USD and has the capacity to treat 60m3 of sludge. The plant will be decommissioned as it was designed for the relief and early recovery phase only.

Operation and maintenance

The overall operation and maintenance of the system is simple. Hydrated Lime Treatment requires a barrel to prepare the lime slurry (e.g. a 50 L plastic barrel). For an even distribution of hydrated lime throughout the sludge, constant mixing is required (either manually or with a mixing pump). A significant amount of manual labor is required, especially for the transport of sludge from the latrines to the treatment site. At field level, the program manager and the sanitation team (supervisors, officers) are in charge of the implementation and the monitoring. Specific daily operation and maintenance is being conducted by local desludging contractors who manage the transportation of the sludge to the site where the system is located.

The system does not require Energy. The costs of the locally available Hydrated Lime, geotextile and filter material (sand, cement, gravel) is relatively inexpensive. Salaries are very low. However because of the hilly terrain, transport of the materials adds additional cost and time to the implementation and must be considered. As part of an appropriate health risk management, costs for personal protective equipment and staff trainings need to be considered. Due to potential health risks when handling Lime, and removal of the dewatered sludge, the process requires trained personnel following health and safety protocols and wearing proper personal protective equipment (PPE).

Daily washing and disinfection of all used equipment is required. Hydrated lime is a powder and corrosive to skin, eyes and lungs. Therefore, adequate PPE must be worn when handling hydrated lime to prevent irritation to eyes, skin, respiratory system, and gastrointestinal tract. Protection from fire and moisture must also be ensured. Lime is an alkaline material that reacts strongly with moisture. Workers must be carefully trained to follow health and safety protocols. The incoming and dewatered sludge of the Geotube contains pathogens; therefore, workers should be equipped with proper PPE. There is no washing facilities available. The site is protected by a fence and drainage is implemented.

Lessons learned

It is essential that the community is informed about the risks related to faecal sludge before the desludging process is initiated. The community needs to be aware of the need to keep a safe distance during the operations, for them and their children and can be part of the planned hygiene promotion activities. Additional awareness raising measures are required to avoid pit latrines being used for solid waste. PPE should be worn and training for involved staff is needed to ensure safety and the proper functioning of the technology.

This technology is appropriate for the stabilisation of faecal sludge in the acute phase of an emergency and can be implemented quickly, where the appropriate geotextile and good quality lime (CaOH2) is available. The infrastructure is not permanent. Once there is land available, the capacity of the system can easily be scaled up by increasing the number of barrels, geotextile tubes and infiltration beds. It is effective in decreasing the sludge volume (through dewatering) which is especially important when sludge needs to be transported elsewhere for end-use or disposal.

Strengths

- Low complexity and cost of the system

- Non-permanent infrastructure

- Rapid implementation

- Possibility of scaling up of capacity by adding more geotextile tubes and filter units

- Can be constructed using local available material, as long as geotextile is available

Add new comment