Upflow filter - Constructed wetland

Description of the emergency context

The humanitarian crisis caused by escalating violence in Myanmar’s Rakhine State has been causing suffering on a catastrophic scale. According to UNHCR estimates, as of 31 December 2019, more than 910,619 (as of UNHCR_Population Factsheet - 20190515) forcibly-displaced Myanmar nationals are residing in Bangladesh. Different organizations have been providing humanitarian aid to these refugees including in the areas of water, sanitation and hygiene (WASH) in the makeshift camps as well as in host communities. Infrastructures and facilities – both those preceding the 2017 influx and those established in response to the influx – are already stretched due to population density. Rohingya community live in bamboo and tarpaulin made temporary shelters. In average, each family consists of 4-5 members and there is more than 50% women and children in the camp considered as vulnerable group.

Out of the 1.2 million people in need of WASH services, thus far the sector has only been able to reach 768,000 people with access to safe sanitation. At the initial stages of the emergency, shallow latrines were constructed, many of which have now been decommissioned. New latrines have been established but some of the emergency latrines are still in use. While septic tanks have been introduced in the camps, space is limited. Combined with limited partner technical expertise in faecal sludge management, this has greatly inhibited the collection and treatment of waste. Daily volumes of faecal sludge removed are much lower than the accumulation rate. It has been stated in Rohingya Humanitarian Crisis Joint Review Plan 2018 (JRP) that due to congestion in the camps, the Sector has been struggling to identify land for final disposal and treatment of faecal sludge. To address faecal sludge management, multiple and phased technical solutions are underway.

In response to the above scenario, Practical Action has intervened in Rohingya camps with a particular focus on faecal sludge management (FSM) which was initially overlooked by most agencies and which has now become a prime focus for Rohingya Response WASH Sector. Since November 2017 (immediately after the influx), Practical Action (PA) has established 18 FSM sites in five different camps (7, 8E, 8W, 9 and 15) which are adaptive to the camp environment. Through these FSM sites, Practical Action has desludged more than 3,500 latrines in these camps which resulted in more than 70,000 beneficiaries. With the existing PA FSM plant operation and coverage in above mentioned camps, PA has extended its service on 108,000 beneficiaries with 10 new FSM plants more along with hygiene promotion services at Ukhiya upazila in Cox’s Bazar district. Practical Action has also extended its technical support to other WaSH agencies i.e. World Vision, Gono Unnoyon Kendro, Christian Aid and Helvetas with 10 FSM plants in camp 8E, 13, 14 and 15. The FSM plant of three chambers adopting up-flow filtration technology has become a reliable method for the regular desludging of latrines as well as for engaging Rohingya community as FSM sanitation workers.

With a proven filtration system, safe water quality (in comparison to other FSM practices in camps), operation friendly plant design and higher level of community engagement (deploying refugees from the Rohingya community as sanitation workers), Practical Action has stepped in camp 7, 8E, 8W, 9, 13, 14 and 15 of Kutupalong and Balukhali makeshift settlements in Ukhiya Upazila, Cox’s Bazar District.

Practical Action FSM plant optimization has been affected by the absence of associated behaviour change communication (BCC) in terms of reaching its desired sanitation impact. As such, a BCC component has now been designed and integrated into the project extension period. According to a need assessment undertaken in Camps 7, 15 and 8W, there is a huge gap in terms of regular BCC interventions with a focus on open defecation.

The Rohingya settlements are quite large to manage in single hand. Various consortiums are activated to response in Rohingya crisis for example camp management, WASH management etc. The consortiums are working in a collaborated way to mitigate the sufferings of the Rohingya people with their resources. WASH sector has a close collaboration with Camp Management to ensure safe water and sanitation accessibility for all Rohingya people. Below is mentioned some local and international actors with active role in the community:

- Site Management Agency: DRC, BRAC, CARE, Christian Aid

- WASH NGOs: Practical Action, TDH, NGO-F, VERC, WVI, BRAC, Friendship, MSF-H, Mukti Cox’s Bazar

- WaSH Governmental agency: DPHE, Office of Civil Surgeon

According to the Health and Wash joint reports, Acute Water Disease cases such as Diarrhea, Cholera, Dysentery, Typhoid etc. are found in camp level. Practical Action is much aware of the wash related diseases and so thus has initiated environment friendly faecal sludge management services with hygiene promotion for the safely disposal of human excreta in camps. PA has also taken necessary measure to ensure health and personal safety for the staffs and sanitation workers.

Description of the treatment process

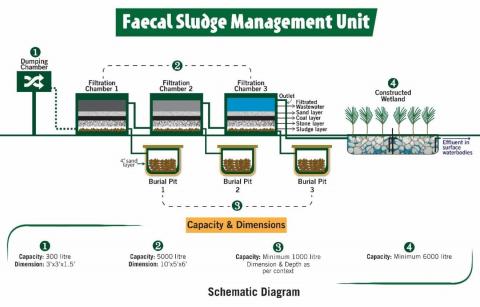

Practical Action has designed Fecal Sludge Treatment unit adopting proven technology of ‘up-flow filtration technique’. A series of filtration chambers has been designed for solid- liquid separation. The raw fecal sludge thickens after separation. The thickened sludge is collected after a certain interval and buried with lime in the designated burial pits having a sand envelop for ensuring safe management. After a certain time, the buried sludge will be converted into compost and if needed, the compost can be excavated to reuse the pits. The liquid portion of the sludge will pass through another two chambers for further filtration and the final treatment of the effluent will take place through a constructed wetland where the pollutants will be absorbed naturally by Canna Indica plants.

This process of up-flow filtration is more environment friendly as all the sludge is kept in the filtration chamber. The main advantage of these plants are that the solid and liquid portion of the sludge are separated. Also another major advantage is that the liquid portion of the sludge is treated with the 3 filtration chambers. There is almost no smell and the desludging process doesn’t follow any manual labor as all the activity is done with proper equipment. One FSM plant on average can cover 220 latrines around its 500 – 800 feet coverage area.

The faecal sludge management unit has four components:

- Dumping chamber

- Filtration chambers

- Constructed wetland and

- Burial pits

Dumping Chamber:

The sludge from toilets are mostly emptied using motorized collection equipment like super sucker or any other centrifugal pump and then dumped into the dumping chamber. The capacity of the dumping chamber is 300 liters. The unwanted materials, if any like cloths, sanitary napkins etc. are screened from the disposed sludge in dumping chamber. From the dumping chamber, sludge enters into the first filtration chamber of the faecal sludge management plant through gravity flow. The valve at the bottom of the dumping chamber regulates the flow of sludge into the filtration unit.

Filtration Chamber:

Each filtration chamber is made of steel structure with waterproof tarpaulin fitted inside the structure with a capacity is 5 m3 per day. Graded filter materials are placed inside the chambers. Each filtration chamber contains valves at its exit to control the outflow of sludge and effluent respectively at different elevations. Each chamber of the filtration unit is interconnected in a baffled system. The sludge flows through the filtration units following ‘up-flow system’. The solid portion of the sludge gets trapped at the bottom part while the liquid portion rises up through the filter media and flows to the next chamber.

Constructed Wetland:

‘Constructed wetland’ is a kind of shallow trench having Canna Indica plants over stone bed to absorb pollutants naturally. The bottom and sidewalls of the trench are lined with waterproof tarpaulin to avoid contamination by any seepage. The capacity of this chamber is at least 6 cum. While the effluent passes through the constructed wetland, the microbial contents inside the effluent form gelatin and the roots of the plants reduce the pathogenic organisms. From the entry into the filtration chamber to the final discharge point, the retention time of the effluent will be maximum 5 days. Finally, the effluent is collected and tested in laboratory to confirm parameters for safe discharge in surface water bodies.

Burial Pit:

The burial pit has been constructed using locally available RCC rings of having maximum depth of 7ft depending on the groundwater level of the site. Each pit contains a sand envelop of 4 inches that acts as a filter media at outer periphery and the bottom of the pit. Once the thickened sludge in the first chamber gets emptied every week and buried into the adjacent pit having sand envelop with lime. The same process takes place in the rest filtration units but rate of deposition is very slow and therefore burial of thicken sludge will be infrequent.

Assessment & design (feasibility)

Practical Action has devised context specific Faecal Sludge Management (FSM) units, adopting ‘upflow filtration technique’ to ensure safe disposal of human waste at hilly terrain in Ukhiya for Rohingya camps. The settlements are so densely populated and having limited access to adequate wash facilities, PA has intervened such a community friendly technology with having no odor and chances of direct physical contamination and so thus achieved reliance as well as trust in the community. The design of MS stainless structure of FSM plant is so much flexible that it can be repaired or decommissioned whenever needed. There are some land specifications like at least 800 square feet plain land above ground water level of 10 feet and having no land slide and flooding risk. Rohingya community has been trained and engaged spontaneously in a way to operate and take care of the FSM units on their own to ensure its security and safeness. Community engagement is essential to sustain its effectiveness for a longer period.

Anal hygiene or anal glad cleansing, refers to hygienic practices that are performed on a person's anus region, usually shortly after defecation. The community in Rohingya camps usually wash anus and buttocks with water using hands in order to remove remnants of feces.

Considering local context, there are several methods of desludging from the latrine pits. Wash agencies did not give much priority on human excreta management at earlier period of influx, so a critical situation did arise when the latrine pits filled up with sludge and community could not have safe access to latrines. Several agencies have come up with various treatment technologies i.e. biological treatment (up-flow filtration, constructed wetlands, biogas plants etc.), chemical treatment (lime stabilization etc.) and on-site treatment. Most of the wash agencies collect sludge from latrine pits directly using hand pump machines and hose pipes. From distant latrines, there are some secondary transfer stations to store sludge temporally before final dumping.

Practical Action has devised context specific Faecal Sludge Management (FSM) units, adopting up-flow filtration technique to ensure safe disposal of human waste at hilly terrain in Ukhiya for Rohigya camps. A series of filtration chambers are for solid-liquid separation. The raw faecal sludge thickens at the lower part of each filtration chamber and will be removed to the burial pits with a sand envelop to ensure safe management. The liquid portion of the sludge will pass through filter media of each chamber and the final treatment of the effluent will be done through a constructed wetland, where the pollutants will be absorbed naturally by Canna Indica plants. Once digested, the buried sludge will be converted into compost and if needed, the compost can be excavated to reuse the pits.

Like other FSM technologies there are a few challenges to implement up-flow technology in camps. Population density in camps being too high, it is difficult to find appropriate land for FSM intervention considering public health and environment. Few of the latrines are situated at low land and are affected by ground water infiltration so it increases frequency of latrine desludging. Sludge collection against gravity is another challenge to find suitable places. Though suitable spaces are harder to find in hilly terrain, PA manages it by modifying plant design to specific land context. Many challenges were faced from the beginning of this project. Through adaptation and gradual changes of the plants these constraints were mitigated.

Construction

An expert team of Practical Action Consulting, a sister concern of Practical Action in Faridpur Upazila of north Bangladesh arranges or outsources all the necessary materials. According to the deed between Practical Action and Practical Action Consulting, they are also responsible to fabricate the FSM structures in camps. For the filter media Practical Action calls for tenders and collects estimated quotation from vendors. Through a comparative statement Practical Action selects a vendor to supply the required filter materials. Vendor selection is the most vital part of installation to ensure quality services for the Rohingya people.

Three tiers of monitoring are maintained during construction and installation of FSM plants. Technical experts ensure the installation process following proper guidelines and confirms the good quality of filter materials. The Field Coordinator and his team of Field Officers provide HR support to ensure proper arrangement of the whole construction and installation progress. The Monitoring, Documentation and Reporting Officer checks all the progress and gives alert for due activities. Despite of these technical and operations team, the Finance and Admin Officer does his designated duties in terms of payment and procurement procedures.

It takes over a month generally 30-45 working days for site selection and site approval from CiC of respective camps. To intervene in a camp, Field Coordinator collects need analysis of FSM plants from respective Camp Wash Focal and then moves to RRRC office for taking approval of FSM intervene in the camps through submitting the need analysis report. In the meantime, the frontline staffs do transect walk and search for suitable places. There are some land specifications like at least 800 square feet site above ground water level of 10 feet and having no land slide risk. Moreover, field officers often avoid top hilly area as it is quite difficult to collect the faecal sludge from the latrine pits against gravitation. Field Officers select random sites with the collaboration of Camp Wash Focal and Site Management. Field Coordinator and Project Engineer then visit the identified sites and finalise the places that meet most of the land specifications. When Govt. authorizes the requested intervention in specific camps, field officers then secure the selected sites for FSM plant.

Project Engineer prepares the layout design for FSM plants considering land context. It usually takes 2-3 days for site preparation and site fencing depending on weather. A mason works with 3/4 assistants to construct RCC basement of the plant in 4-5 days. A sanitation worker takes care and waters the basement for 3 consequent days. An expert team of Practical Action Consulting fabricates the FSM structure within 3-4 days. A water leak test is run for 5-7 days to assess any leakage of fabrication before placing the filter medias in the chambers. Parallel construction of burial pits, soak well and wetland goes on within this period of fabrication and water leak test. After a successful water leak test, filter materials are placed in the chambers within 3-4 days and roofing is essential to protect the chambers from rain water infiltration. Water for filtration chamber leak test is a resource temporally needed for construction and installation.

Sanitation workers are provided caps, goggles, gloves, gum boots and apron for their personal safety to avoid direct contact with the human excreta. They wear the PPEs for their regular services. The materials are provided regularly to ensure health and protection safety of the sanitation workers which itself is a challenge for check and balance between estimated budget and safety. The frequency of desludging activity decelerates during the monsoon season due to heavy rainfall and risk of land sliding. It becomes difficult to walk in the slippery pathways carrying heavy weighted machines.

Operation and maintenance

Description of O&M activities:

- HR: Field Officers, volunteer, sanitation worker

- Equipment: Diesel engine machine, hi-cap sucker, hose pipes, joint cuff links,

- Frequency: 4 times in a week, 60 – 80 pits per week

- Objectives: to provide safe sanitation services in over populated camps

- Challenges: improper maintenance of latrines, accessibility to the pits, solid garbage dumped in pits, lack of water for sludge stabilization

Process parameters:

Inlet and outlet water quality test results show that the treated water is equivalent to industrial water quality.

BOD reduction 60%

COD reduction 55%

pH increase 76%, with an average of 7.6

The output sludge production in comparison to sludge input flow is 50 kg/m3.

Odor is reduced completely through coal layer

Security and safeness during O&M:

PPE: caps, goggles, gloves, gum boots, apron

Safety rules: Sanitation workers must need to wear PPE during sludge collection and dumping in the plant.

Responsibilities: FFs and volunteers to ensure sanitation workers are using PPE properly.

Challenges: PPEs to change periodically

Washing facilities are available.

The site is protected by a fence.

Drainage is implemented.

Final outputs:

Environmental friendly: sludge cannot contaminate earth as it is stored in well protected (tarpaulin and stainless steel made chamber)

Raw sludge is treated through 3 layers of filter media

Solid sludge is used as a fertilizer

Treatment challenges:

Filter materials clogging due to excessive level of solid sludge, long distance for water quality test (Camp to CUET, no authorized lab nearby), inlet clogging

Logistic challenges:

High cap sucker damage, hose pipe leakage, machine disruption, gate valve clogging

Add new comment