Anaerobic Baffled Reactor - maturation ponds

Description of the emergency context

Pauktaw is a zone that was directly affected by the October 2012 ethnic conflict. IDPs, Host Communities and isolated villages are facing an immediate need for water, sanitation and hygiene education as well as access to health and nutrition services. This is especially important given the crowded conditions in most of these neighborhoods.

Sin Thet Maw camp, in Pauktaw is supported for the WASH activities by Save the Children. In term of sanitation, around 430 latrines have been built for this camp hosting 682 households and 2523 beneficiaries. The waterproof aspect of the latrine pits implies a filling of the latrines pits. Once the pit full, create another pit and latrine is not possible for a reason of land availability. Like for the Sittwe camps, desludging of the latrines and treatment of the sludge have been considered.

Community

- Dimensions or area: 800,000 square feet (7.5 hectares)

- Livelihood: mainly fishery

- Type of shelter/house: long house shelter

- HHs dimensions: average of 3.7 individuals per household

- Living area of community: Sin Thet Maw IDP camp, 20° 4'4.33"N, 92°59'33.56"E, 35min boat trip from Sittwe Golden River Jetty)

- Population increase/decrease forecast: 6-10% annual growth

- Type of site: semi-permanent camp

- Type of context: rural

- Other WaSH activities implemented in the community: hygiene promotion, water treatment and distribution, drainage, solid waste management.

- Local and international WaSH institutions with WaSH active role in the community and specific partnerships: only Save The Children is the WASH service provider

- Main waterborne diseases: AWD

Description of the treatment process

- A first physical treatment by filtering through a grid the object present,

- A second physical treatment in a sludge drying bed: a settlement tank to separate the sludge into a solid part and a liquid part, which is clearly the first module in terms of construction.

- A third physical treatment: a settler to polish the sedimentation,

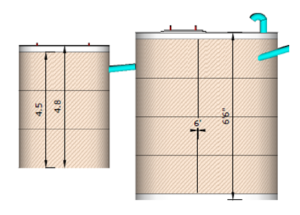

- A first biological treatment: an Anaerobic Baffled Reactor (ABR) to degrade the suspended and dissolved solids,

- A second biological treatment: two aerobic maturation pond to remove pathogens, on which is added a polishing pond.

Assessment & design (feasibility)

During the monsoon 2014, temporary piezometer have been set to ensure the highest groundwater level into the compound. The groundwater level measurement is 2.5 feet from the surface.

- Inlet sludge parameters measured and their mean value: CODin = 35,000 mg/l ; BODin = 8,000 mg/l.

- Mean number of users per pit: 14.4 user per pit

- Flush or dry toilet: dry

- Type of material for anal cleansing: water

- Presence of solid waste in the pits: yes

- Desludging and transportation system: motorized desludging

- Desludging organizations: formal, well equipped, covering the needs

Local safety requirements:

- integrated overall (covering the hair)

- Rubber gloves,

- Boots,

- Masks,

- Bathing space

Other information:

- Production of sludge per person per day considered for the design: 1.92L

- Design time life of the plant: years

- Design formulas used: See design in annex – BORDA formulas were used.

- Reference documents used for the design of the plant: Decentralised Wastewater Treatment Systems (DEWATS) and Sanitation in Developing Countries

- Special skills necessary for the design: Civil engineering / hydrogeology / biology / fluid mechanics

- Mitigation of the local constraints: high water table, flood prone area, earthquakes.

- Type of climate: tropical monsoon climate

Construction

Construction material of the different treatment modules:

- Cement

- Sand

- Gravel

- Bricks

- Iron bars

- PVC pipes & fittings

- GI pipes & fittings

- Clay (bricks)

- Zinc sheetings

- Wooden beams / timber

Other information:

- Construction and installation methodology: camp based contractor

- Time needed for construction and installation: 7 months

- Area of the total land used and area of the treatment modules: 1,725m2

- Special skills necessary for the construction of the plant: Masons, carpenters, civil engineer, hydrogeologist, environmental health specialist

Operation and maintenance

- Number of workers needed to operate and their skill level: 6 workers operate and maintain the plant on a regular basis.

- Spare parts needed and availability locally/internationally: STS require fuel (for the pumps), water testing consumables and minor maintenance budgeted for a cost of $ 200 monthly.

- Social acceptance: Good because STS is settle at a reasonable distance of the households’ shelters

- Washing facilities available: Bathing space

- Access to the plant: Walking or tractor

- Site protected by a fence: Yes

Lessons learned

Recommendations:

- A design with sufficient treatment capacity

- Construction period not during water scarcity period and neither during monsoon.

Strengths

- Well designed

- Good location

- Treatment capacity is sufficient

Weaknesses

- Challenging to ensure a proper handover to the Government for the operation and maintenance of the facility after camp closure.

- Not an income generating activity.

Add new comment