IOM Decentralized Wastewater Treatment System (DEWATS)in the Rohingya refugee camps in Cox’s Bazar, Bangladesh.

Description of the emergency context

Some 929,606 Rohingya refugees currently reside in 33 congested camps formally designated by the Government of Bangladesh. Following the outbreak of extreme violence in Rakhine State of Myanmar on 25 August 2017, an estimated 687,000 Rohingya refugees crossed the border into Cox’s Bazar, Bangladesh. Persecution has driven Rohingya refugees across the border into Bangladesh repeatedly. Significant influxes have occurred following violence in Rakhine State in 1978, 1992, 2012, and again in 2016. By far the largest and fastest refugee influx from Myanmar into Bangladesh began in August 2017.

The IOM WASH Unit in Bangladesh is the Area Focal Agency for 12 Rohingya camps and has been working in Cox’s Bazar since 2014. From the influx in August 2017, the unit has been coordinating the overall WASH response in its area of responsibility. IOM also works with partner agencies to ensure the ongoing operation and maintenance (O&M) of facilities.

In highly congested settings, such as the Rohingya camps, WASH actors face challenges to deliver faecal sludge treatment processes which provide an effective removal of pathogens. The challenges are largely due to limitations on space, which places constraints on to the ability to include appropriate, safe and sustainable aerobic processes in the treatment train.

Description of the treatment process

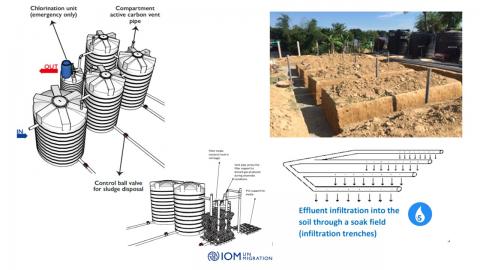

In 2018, the IOM WASH programme designed a new treatment mechanism—the Decentralized Wastewater Treatment System (DEWATS). The treatment mechanism works by solids/liquid separation through settlement and filtration as well as digestion of solids under anaerobic conditions. The Plastic DEWATS are composed of two processes: The Anaerobic Treatment System (ATS, in plastic tanks with filter material). The 2 first tanks allow the separation of liquid and solid as a traditional septic tank and the next tanks are filled with coconut husks to allow upflow filtration of the wastewater.

- It can serve more than 5000 ppl with only a surface of 120m2. So It doesn’t require a lot of space. And we know that land allocation for faecal sludge treatment systems is very often a challenge in congested humanitarian settings.

- Its Environmentally friendly - there is no need of power supply or chemicals

- Its easy to operate and maintained. It doesn’t require specific skills

- Material is cheap and locally available.

- The system is totally sealed. There is no smell or exposure to wastewater

- There is good treatment performance before infiltration with 96% of reduction of faecal coliform and 99.6% of reduction of helminths, 87% reduction of BOD, 83% reduction of COD; TSS reduction 96%.

Assessment & design (feasibility)

The Site identification is the first stage of project implementation and is essential. The camps are extremely congested, and it can be very challenging to identify a suitable location to accommodate the DEWATS. Some key parameters must be considered during the assessment:

- The population targeted considering that one system can serve maximum 5,170 users.

- The surface area of the site: 65 m2 of land needed for the ATS and 52m2 of land required for infiltration trenches.

- The soil infiltration rate must be tested and calculated for each site.

- The groundwater levels must be measured. If the water table in certain periods of year reaches the depth of 2.5 meters or less (i.e. less than 1.5 meters space from the bottom of the trench), the desludging pits and infiltration trenches won’t be fully operational during the year.

- Flood prone area must be avoided imperatively.

- The infiltration trenches must be located at least 30m from the nearest water point.

Construction

Site development:

he topography in the camps varies. Most of the camps are in hilly areas. Valleys should be avoided as they can be prone to flooding or zone that have shallow water table which is not suitable for DEWATS. Consequently, most of the suitable sites for DEWATS installation will be identified on the hillsides. It’s essential to coordinate with site management, site development units and SMEP to assess the risk of landslides and to take action through slope protection and site development. The site must be properly leveled and compacted to accommodate the different components of DEWATS and ensure stability when the system will be operational.

Safety:

The contractor in charge of construction should have clear EHS measures in place. They should provide to workers involved in the construction personal protective equipment (PPE: including safety shoes, helmets and gloves).

The contractor is in charge to identify the risks linked to the construction work and briefed the workers accordingly.

The contractor is in charge to ensure dignified working conditions to the workers in the field by behaving with respect, providing safe working conditions, weather protection (against sun and rain), limited working hours, proper tools and equipment, etc. More specifications are defined within IOM agreement.

The contractor prevents public access to the construction site by clear sign and preventive measures adapted to refugees (site fencing, guard, sign board writing in Burmese, etc.)

Environment:

All waste produced by the construction are properly collected and disposed by the contractor in order to mitigate any negative impact on the environment and public health.

COVID-19 measures:

The IOM WASH programme in Cox’s Bazar has made adaptations to COVID-19 throughout 2020 through specific infection, prevention and control measures. It is expected that these will continue to be utilized in 2021 to ensure safe delivery, including training provided with adherence to physical distancing guidelines, wearing of face masks, adequate hand hygiene and adequate cleaning and disinfection of materials.

Inspection:

All tools and work equipment must be inspected regularly. IOM supervisor and contractor manager should be responsible for this continuous inspection. Inspections can take the form of a check list.

Refer to the BoQ for more details

Operation and maintenance

DEWATS performance:

According to the faecal sludge quality monitoring, the reduction of parameters tested between inlet and outlet is significant and demonstrates the effectiveness of the treatment mechanism.

The reduction is: FC = 96%; TS = 70%; COD = 83%; BOD=87%; TN=60%; TP =76%; and helminths = 99,6%. It is also showing that 80% of raw sludge samples tested with presence of vibrio cholera are free of this pathogen after treatment.

The average result of FC is 16,880 CFU/100ml and, considering that WHO standards for reuse of wastewater in agriculture is 20.000-40.000 cfu/100 ml, the quality of effluent after treatment would allow the reuse for irrigation. However, the quality of raw sludge is variable (which impacts the consistency of results) and the congestion in the camps cannot allow the reuse for irrigation.

The infiltration process remains an essential component of process where the soil characteristic is a key factor for the system. In case of any emergency like outbreak and it is decided that the effluent need to be disinfected, IP must add chlorine at the final stage to achieve a concentration of 15mg/l in tank 5 (2000liters).

Desludging and O&M (refer to SOP):

1 team of 4 desludgers should be operationational to allow the optimum volume of faecal sludge per day (3.1m3 per day). Using two desludging pumps in series. One surface pump should be installed next to the latrines pits and moved during each desludging operation and a second pump should be installed permanently close to DEWATS. This second pump will allow to empty the pipe between the two pumps and reduce the risk of leaking after filling the sludge pit.

DEWATS is a recent technology and even if it is designed for minimum O&M requirements, it’s essential for partners to monitor the system on daily basis with dedicated trained staff in order to prevent and identify problems. You will find in the SOP examples of challenges that field staff could potentially face during operations

Monitoring tool should be used and filled on daily basis

Lessons learned

All volume of wastewater disposed and released by the DEWATS must be recorded in the monitoring tool and properly analyzed to ensure the proper use of the facility.

Possible additional treatment solution could be adapted to the DEWATS to improve the reduction of pathogens and discharge of effluent in the environment or reuse for irrigation.

Strengths

- It doesn’t require a lot of space.

- Its Environmentally friendly - there is no need of power supply or chemicals

- Its easy to operate and maintained. It doesn’t require specific skills. Low OPEX

- Material is cheap and locally available. Low CAPEX

- The system is totally sealed. There is no smell or exposure to wastewater

Weaknesses

The infiltration process remains an essential component of process where the soil characteristic is a key factor for the system. Valleys should be avoided as they can be prone to flooding or zone that have shallow water table which is not suitable for DEWATS. Consequently, most of the suitable sites for DEWATS installation will be identified on the hillsides

Add new comment