Emergency Faecal Sludge Management – Lime Treatment, Bentiu, South Sudan

Organisation that implemented the case study

Description of the emergency context

Bentiu IDP camp located in Unity state, South Sudan hosts a population of 102,811 as of October population count. The camp has been in existence since 2014 as a Protection of civilian Site (PoC) established after the conflict displacement. In March 2021, the PoC transited to and IDP camp. In 2021, Unity state experienced severe flooding and in September 2021, the flood water reached Bentiu with water levels picking significantly around mid-November 2021 to an average water level of 1.2m. The rising water levels forced residents to flee their homes to nearby higher grounds, destroyed livelihoods and infrastructure, disrupted service delivery, and cut-off the supply chain; leaving displaced population overcrowded in temporary sites and to protect human lives form the flood treats dykes were constructed around Bentiu.

Incident resulting in Establishing the FSM:

Since September 2021, flood water levels continued to rise significantly in Bentiu putting pressure on the existing dykes. On the 9th October 2022, Bentiu received heavy rains, adding more pressure on the dykes and this pressure resulted in the dyke breach at the western perimeter of the IDP camp. This dyke breach resulted in flooding of access road making the road impassible to the solid and liquid waste treatment sites (Waste Stabilization ponds) which are located approximately 1 km from the IDP camp. Bentiu IDP camp Despite the fact the road to the oxidation ponds was flooded and impassible, the increased flood levels have also affected the ponds with flood water levels rising above the perimeter walls of the maturation and facultative ponds being flooded. This left with no option of managing and disposal of both liquid and solid waste from the camp.

Provision of sanitation in the IDP is through onsite latrines constructed around the blocks on the ‘sanitation corridor”. The common design is a block with four stance latrines with average pit depth of 3.7m *1m wide*3.8m length (14m3). The total number of communal latrines in the Bentiu IDP camp is around 2400 stances. The latrines are lined with CGI sheets and get filled up on average after 3 months of construction promoting the need of desludging. Desludging in the camp is done and coordinated by IOM across the camp, through a fleet of tractors mounted with desludging tanks and disposed to the waste stabilization Ponds, situated approximately 0.8km away from the camp.

Description of the treatment process

IOM with support from MSF established an emergency faecal sludge management plant (FSM) within the IDP camp in order to manage liquid waste in the camp to avert any public health hazard since the access to the oxidation ponds was cut off by the floods. The operation of the emergency FSM plant started from the 13th October 2022 until 22 January 2023.

IOM used lime to treat and ensure pathogen reduction of the influent by raising of the pH levels to high alkaline conditions.

Assessment & design (feasibility)

Lime was used to treat and ensure pathogen reduction of the influent by raising of the pH levels to high alkaline. At its establishment/ inception IOM has been treating on average a minimum 40m3 of liquid waste per day at the plant, however this was far below the faecal sludge production levels in the IDP camps, and more latrines were observed to be filling up and in need of desludging. The minimum of 40m3 per day was done considering lime treatment requirement. This called for increase in the treatment capacity to a daily average of 120m3 to reduce the public and environmental health risk in the IDP camp. Additional treatment tanks 1*T70m3 and 1*T45 m3 tanks installed to accommodate the treatment requirements including installation of additional drying sludge drying beds.

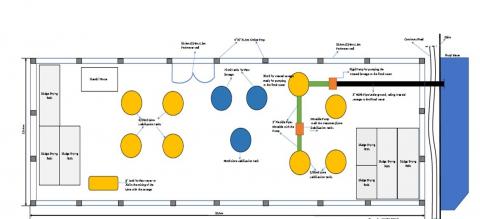

Annex 2: Schematic layout of the Bentiu Emergency FSM plant

Construction

The Bentiu emergency FSM is on a 2019 square meters area with a semi semi-permanent perimeter fence wall. Initially, the plant consisted of 8*30 cubic lime stabilization tanks and 1*70 cubic influent receiving tank. Due to the increased need for treatment additional capacity was installed which is 1*70 cubic tank to add on the capacity of receiving storage and 1* 45 cubic tank for lime stabilization. The schematic layout of the plat is as in annex 2.

Operation and maintenance

Area of the Plant – Bentiu IDP camp Emergency FSM lime treatment site has a surface area of 2019 square meters including the dry beds.

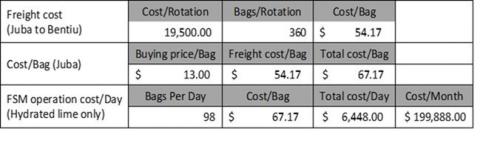

Summary of the Emergency FSM operational cost:

The greater part of the operational cost is calcium hydroxide (hydrated lime), it is shipped from the capital city Juba through airlifting. The Purchase price for 1*25kg bag of lime is at $13.00 and shipping cost through airlifting is at $54.17 bringing to a total of $67.17 per 25kg bag (purchase and transport).

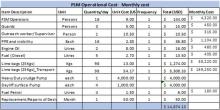

Additional operational cost include equipment, site maintenance, fencing, daily casuals incentives, pumps & piping, fuel, PPE as summarized in table 1 and Table 2 annex

A total of 16 operators were selected from the beneficiary community, trained and capacitated to perform daily operation, treatment and maintenance of the system.

Lessons learned

• Lime powder is corrosive and can affect the skin and respiratory system, and this calls for training of the staff to ensure safety protocols and proper PPE to the operators.

• Weather affects the drying period of the sludge from the dry beds, longer time to dry during the rainy days and 5-7 days during dry periods of temperature above 30oC.

•Adequate mixing of sludge is an important aspect to ensure effective lime treatment and to achieve this, lime to be mixed first with raw water, form a slurry after which is mixed with the sludge.

Strengths

• FSM plant easy and quick to set up and start treatment operations for emergency settings to avert public health challenges.

Weaknesses

Even though the Lime treatment plant is easy to set up, in the case of Bentiu, there is need for prepositioning of lime. In Bentiu, the cost of lime procurement and transportation is high upto $67.17/ bag.

Road access is a challenge with only a short window per year to use the road, living air transport as the main option. In Bentiu, the FSM plant can only be effective for a shorter period (emergency) considering the daily treatment needs and high operational cost.

Add new comment