Baharka Camp Grey-water Treatment System

Description of the emergency context

In 2018, the city of Erbil has experienced water shortages as a result of the ongoing heat waves sweeping the Kurdish Region of Iraq. Besides drought conditions, authorities have also identified rapid population growth and an inherent waste of fresh water by the general public increasing the systemic water shortage.

Finally, as a result of untreated wastewater disposal, the surface- and ground-water resources are being polluted by harmful contaminants on a daily basis.

In Iraq thousands of people have been forced to leave their homes as the militant group Islamic State (IS) advances. Around 200,000 internally displaced persons (IDPs) are living in formal camps and over 100,000 IDPs living in informal sites throughout the country. From the initial displacement of 3 million persons from 2014 onwards, mass returns to areas of origin have occurred. However, there still remains a significant need to support those still displaced with humanitarian assistance

In 2019, the Baharka camp was competing 4528 individual in the camp

Description of the treatment process

Assessment & design (feasibility)

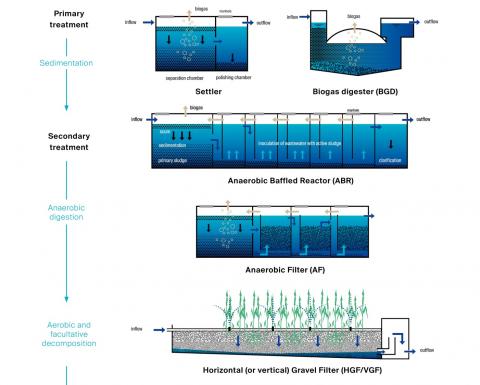

Greas trap : Traps oil and grease to be collected and removed from the wastewater before further treatment.

Composting pit : Absorbs smells coming from the ventilation pipe. The filter is filled with tree leaves to produce fertiliser.

Settling tank: Remove suspended solids by sedimentation. The low flow velocity in the settler allows settleable particles to sink to the bottom, while constituents lighter than water float to the surface.

Anaerobic filter : Traps particles and degrades organic matter by the active biofilm at the surface of the filter material.

Horizontal Plant gravel Filter : Is a large gravel and sand-filled basin that is planted with wetland vegetation. The material filters out particles and micro organisms and the vegetation transfers a small amount of oxygen to the roots zone allowing aerobic bacteria to colonise the area and eradicate organisms.

Collection tank : Stores the treated wastewater to provide a steady water supply.

UV light : Inactivates/Destroys pathogenic organisms to prevent the spread of water-borne diseases.

Construction

In September 2018 BORDA began construction of a waste water treatment facility in Baharka refugee camp for Iraqi IDP’s (Internally Displaced People). The system treats 20 m³ of grey-water per day. This water comes from the 298 camp dwellings housing 725 families. The treated wastewater replaces the 20 m³ of fresh water required to irrigate the existing 6 greenhouses inside the camp. The total cost of the project is equivalent to the cost of 3 years of water trucking

Operation and maintenance

Lessons learned

1-It is better to maintain the system on weekly, monthly and yearly based according to the need.

2-It is better to implement the construction in summer season.

3-It is better to give the excavation walls an stable slope to avoid collapse.

Strengths

1-The system doesn't need to add any chemical for the treatment prosses.

2-It doesn't need high electric power, only few voltage is enough for the UV light and the pump.

3-It can treat wastewater from different sources such as domestic or industrial wastewater.

4-It can be designed in various capacities from 1 m3 to 1000 m3 per day.

5-The operation and maintenance is cheap and simple.

6-The capital cost and the operational cost is not so high.

7-It can be build by local materials.

8-It doesn't need a big space because most of the components are underground and the surface can be used for different purposes such as cars parking area.

Weaknesses

1-In case of not maintaining the system for a long period, the filter media will be clogged, the reeds in the HPGF will die , the odor emission will be more, and finally the efficiency of the system will reduce.

2-During rainy season, the construction process will be slow since most of the components are underground and the ground need to be excavated, but heavy rain causes the excavation be filled with mud and it need to be clean again before constructing the components.

3-Excavation in a loose soil causes collapse.

Add new comment